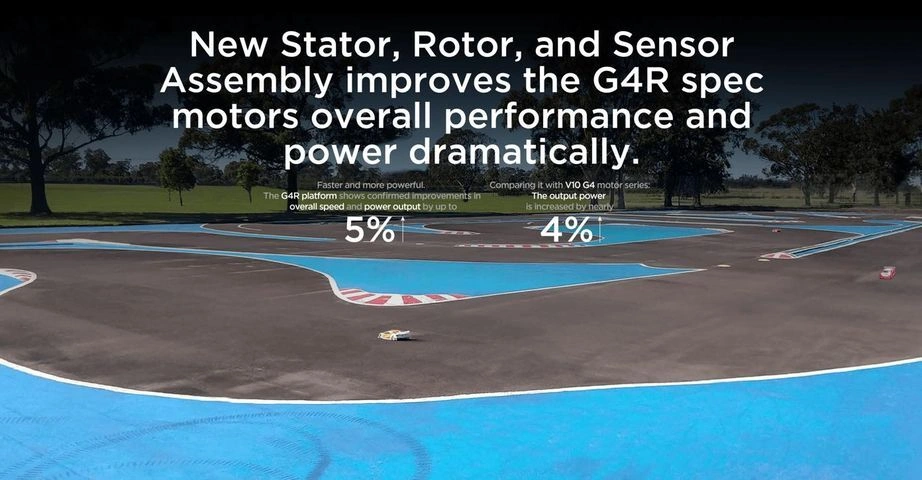

Ultra-large output power

The new generation of the V1O G4 motor is greatly optimized. The stator is redesigned for higher efficiency and is equipped with an ultra-high grade custom magnetic ring rotor to provide maximum torque output and an increase in output power by 5%

Low internal resistance, high efficiency

The internal resistance is reduced by about 4%, resulting in a more efficient and cooler temperature of the motor.

Excellent heat dissipation

The motor adopts a fully exposed stator core and is directly exposed to the air for excellent heat dissipation. The outer diameter is maximized to increase the stator heat dissipation area by 25.6% compared to the v10 G3R motor.

High-precision Endbell plate

The motor is equipped with a high-precision end bell plate. lt uses high-quality structural components to greatly improves the consistency and structural stability of the poweroutput at all times.

Easy to disassemble, clean and maintain

The motor adopts a modular structural design, which is convenient for daily maintenance. This effectively prolongs the service life of the motor and maintains the efficiency of the motor.

Dual sensor port design for easy wiring

The dual output socket at the rear of the motor is designed to meet various wiring needs. The customized dust plug is provided to prevent the unused socket from having dirt entering.

Optional Rotor is available

The 13.5T-21.5T motor is equipped with a super magnetic rotor (PN308204445) as standard at the factory. This is the most suitable rotor for'Blinky' Stock racing applications. The optional magnetic rotor (PN 30820416) is better suited for BOOST competition applications, with higher power output and lower motor temperature. for BOOST competition applications, with higher power output and lower motor temperature.

High-quality material and advanced design in the industry

The outlet terminals adopt custom-widened U-shaped gold-plated curved copper strips with extremely low internal resistance and increase the gap between the copper strips, which makes it easy to weld.

A large open-hole structure at the rear of the motor provides an excellent heat dissipation effect for endplate components.

The use of high-performance and high-quality stator, high-temperature resistant wire(200°C), high temperature resistant explosion-proof rotor(180°C), and international grade bearings.